end suction pump vs inline pump

This end suction pump choice is also a candidate for water service flow rates above about 3000 to 5000 gpm even though many pump users would probably be looking at Double Suction between bearing split case pumps in this flow range. Both end-suction centrifugal pumps and double-suction centrifugal pumps are similar with similar advantages and disadvantages.

4030 End Suction Base Mounted Pumps Ace Products

The pump discharges the fluid at 90 degrees to the suction.

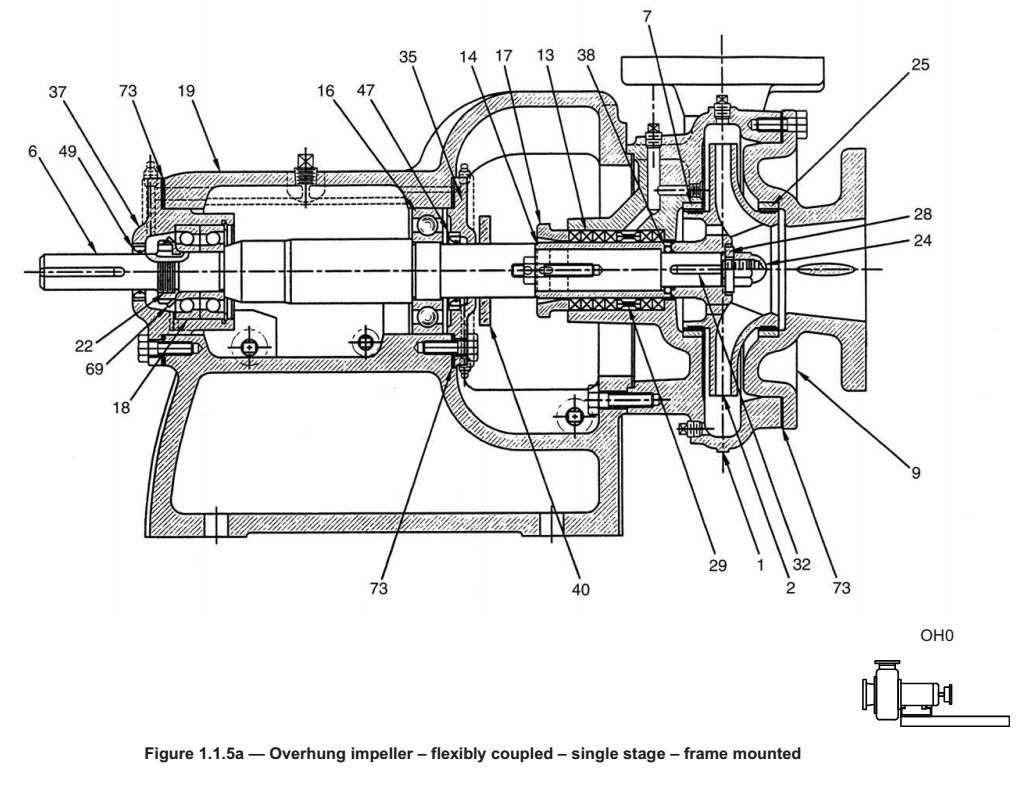

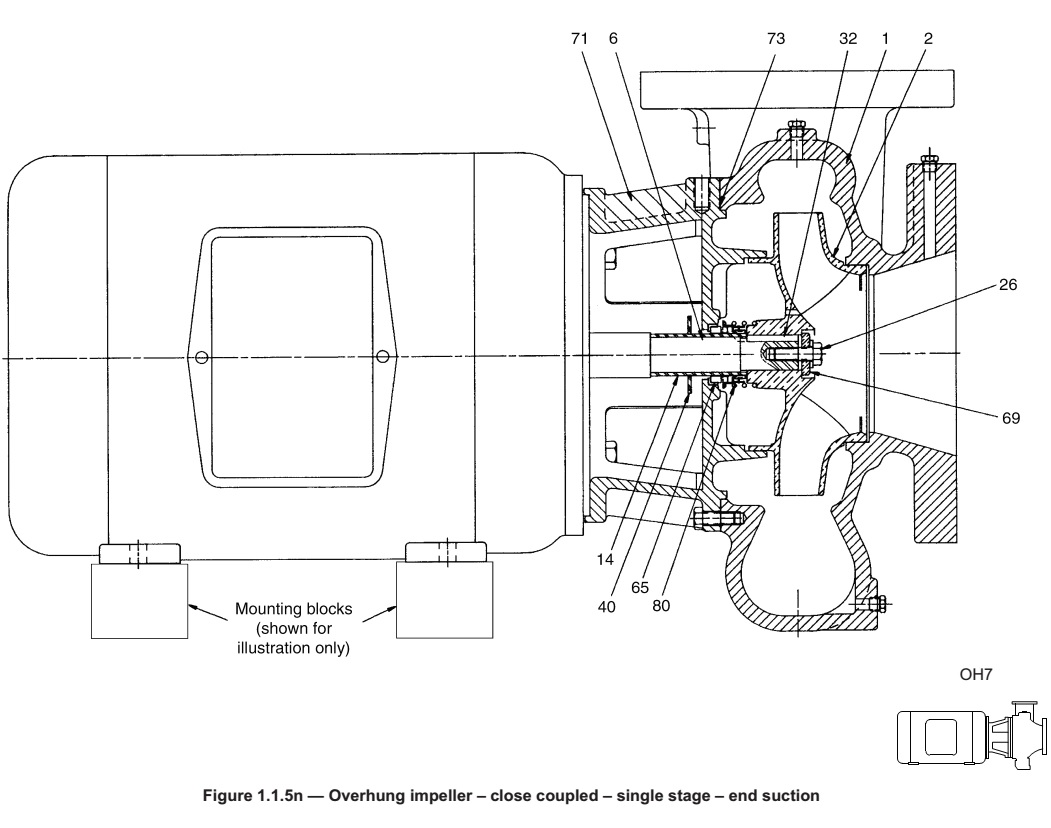

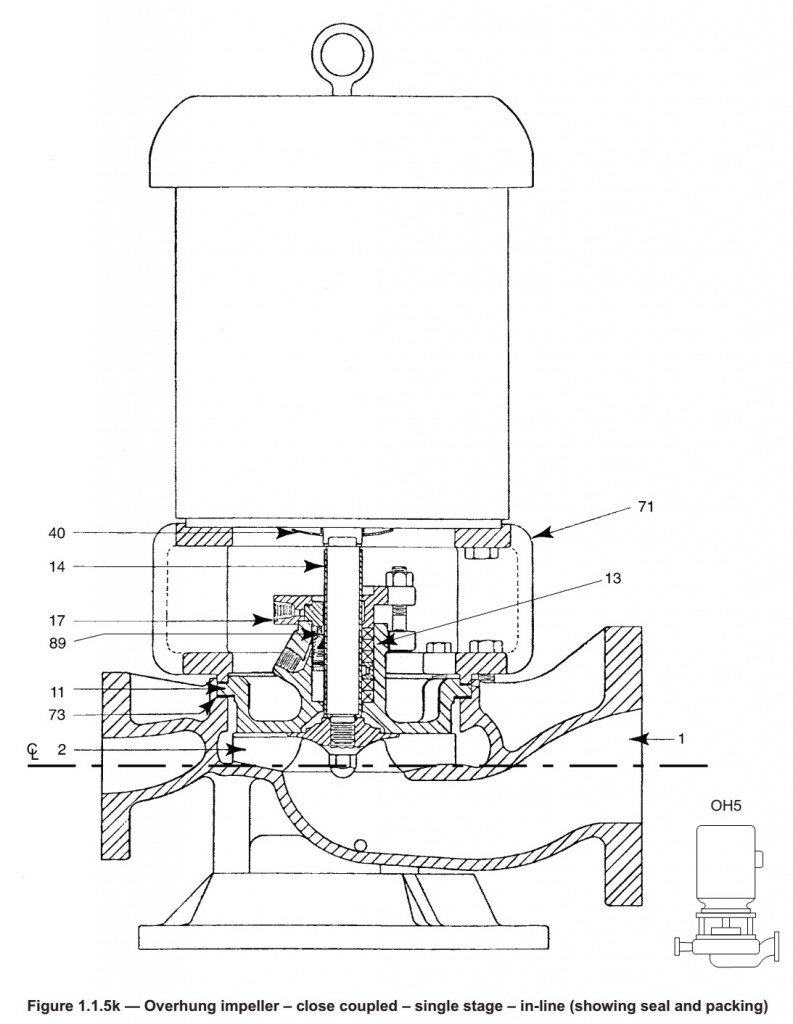

. Usually of overhung hung impeller type in which the impeller is mounted on the end of a shaft which is overhung from its bearing. The pump is a centrifugal single stage single suction type. Double suction inline pumps have bushings instead of bearings which should be inspected whenever the pump seal is serviced.

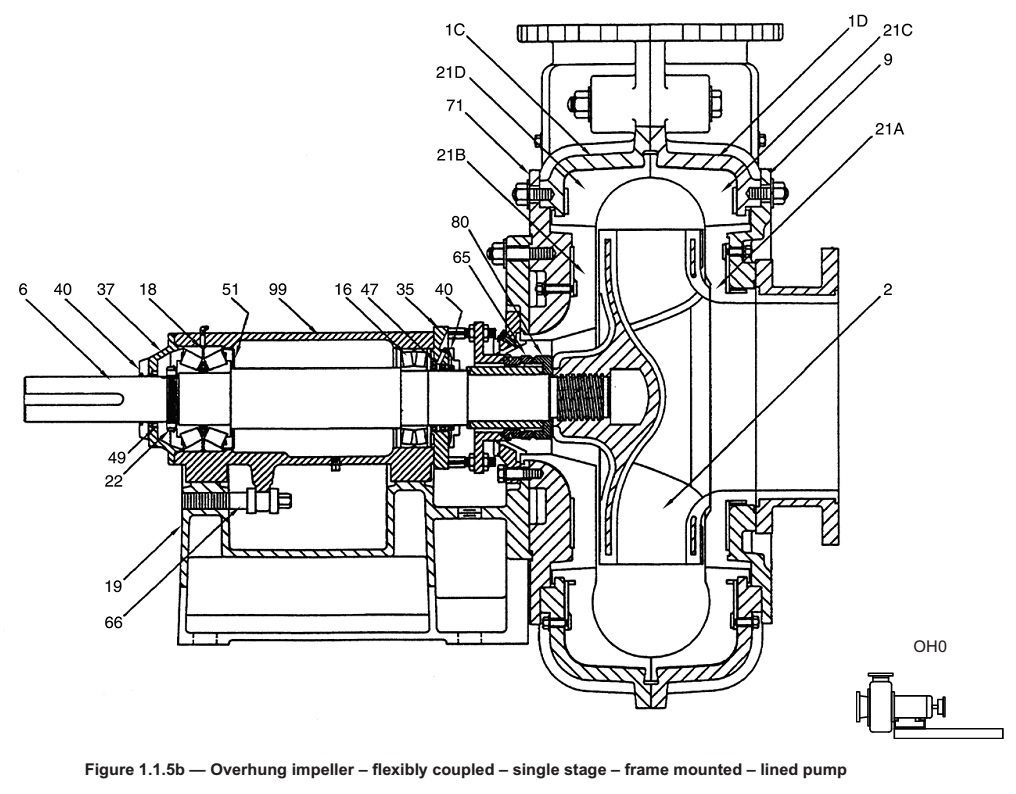

A lined end-suction pump is a type of end-suction pump designed with a. The inlet pipe diameter is larger than the outlet pipe diameter. Usually this is where the discussion between end-suction pumps and inline pumps begins.

End suction pumps are centrifugal pumps consisting of an axial inlet for suction. The coupler joins the motor shaft to the pump shaft. It covers a much smaller footprint than horizontal pump and motor configurations.

Due to their simplicity end-suction pumps are the most common centrifugal pumps used in most applications. It covers a much smaller footprint than horizontal pump and motor configurations. Contact Our Team Today.

A pump moves fluid from one location to another. Orders Over 99 Ship Free. The big difference is that physically the suction includes a longer path to the eye of the impeller allowing both the suction and discharge connections to be inline with the piping.

Hello What is so special about grundfos pumps. End-suction pumps generally have a more compact design than split-case pumps. However there are several types of pumps that you can use to meet your fluid transportation requirements.

Worthy of 6 Stars. Fluid is able to flow through the pump easier requiring less suction pressure to feed the pump. As the name implies the horizontal centrifugal inline pump has a shaft that is placed horizontally.

Company at which i am doing internship is having almost every pump of grundfos. What is the difference between the vertical and horizontal end suction pump. Generally the single-stage end suction typedouble suction type pipeline is fed inouthorizontal in and out.

Split-case pumps are typically used for large hydronic systems. The water inlet on the impeller side is end-suction single suction and the two Side water is called double suction. End-suction pumps are typically used for small- to medium-sized systems.

And one more doubt How do i decide whether end suction pump is to be used or inline pump is to be used. Vertical in-line pumps are typically used in small- to large-scale projects so these pumps are another option. Large double suction base-mounted pumps can be provided with various suction and discharge configurations.

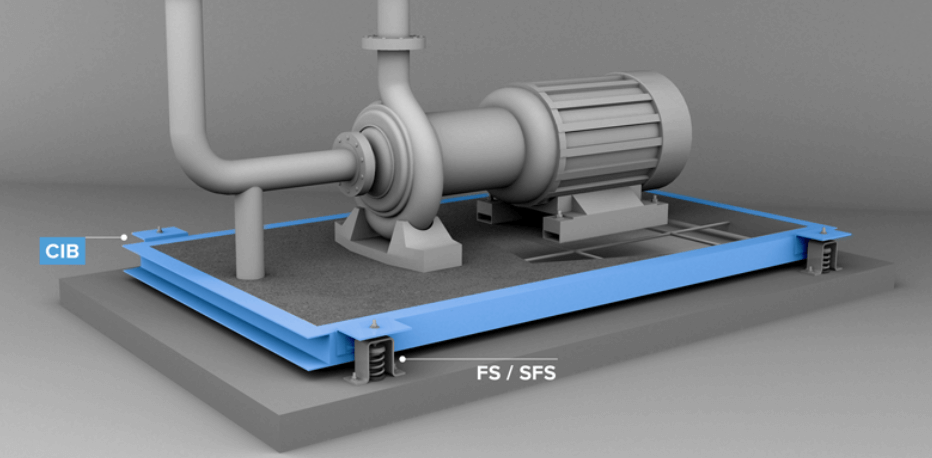

In many industrial and mining applications the liquid being pump is extremely abrasive. How do you choose the correct one. The inline pump is a derivative of the end suction where the suction and discharge is on the same axis which simplifies the installation into the piping systems without the need for expensive foundations.

Ad Prepare For Your Next Job With the Best Pumps Online From Leading Manufacturers. Inline centrifugal pumps are commonly used in building applications where space is very limited. The vertical inline close-coupled VICC pump operates internally on the same principle as end suction pumps.

Shop From Experts See The Results. The only difference between the two is. Inline Pumps The inlet and outlet points in the inline pumps are along the same axis.

End Suction Pump. As this system is a medium-sized system the end-suction pump is a potential option. Ad Highly Efficient Versatile Simple To Use Designs.

I Couldnt Be More Impressed With SupplyHouse. This manual covers the installation operation and maintenance of Patterson Pump end suction pumps. Horizontal pumps are of end suction back pull out design in accordance with DIN 24255 and ISO 2858.

Because of their simplicity of design end-suction pumps also tend to have a lower up-front cost than other comparable pumps. Benefits of Split Case Pumps. Ad Heavy-Duty Fuel Hand Pumps Mount On Drums For Easy Access.

NPSHr is lower for inline pumps due to its design. Ad The Weathers Getting Warmer Meaning its Pond Season. On the other hand the vertical inline pump has a shaft that is positioned vertically.

Double Suction Inline These pumps can be quite large and are typically double suction when the pump gets over 12 piping flange size. Models for close rigid coupling flexible coupling and spacer coupling. It is either placed between the bearings or overhung.

A single suction pump having its suction nozzle on the opposite side of the casing from the stuffing box and having the face of the suction nozzle perpendicular to the longitudinal axis of the shaft. Double suction between bearing split case pumps see figure 3. The inline pump is a derivative of the end suction where the suction and discharge is on the same axis which simplifies the installation into the piping systems without the need for expensive foundations.

Pumping range from 5 to 1000 m 3 h CNDV630. 3500 m 3 h. Just like the above type the design of the shaft is overhang and is radial split.

End-suction pumpsare actually single-suction pumps. Get The Job Done. The power can be made large and the efficiency is higher than the vertical type.

Grundfos Pump Inline Vs End Suction Centrifugal Pump - posted in Industrial Professionals. End-Suction vs Inline Pumps. Inline centrifugal pumps are commonly used in building applications where.

Pump the impact on the pipeline is relatively small. In these sort of applications it often makes sense to design certain parts of the pump for inevitable wear and failure. This makes them good options when space is at a premium and you need a pump with the small footprint.

An end suction pump is usually mounted in the horizontal position. By Kelly Patterson on October 19 2016. When properly installed and when given reasonable care and maintenance centrifugal pumps should operate satisfactorily for a long period of time.

Double Suction Between Bearing Split Case Pumps. Inline pumps as the name suggests are traditionally mounted in the piping line and the weight of the pump is supported by the pipe andor pipe hangers. The VICC pump shares with its end suction cousin the.

End Suction Pumps And Split Case Pumps What S The Difference

Why An Inline Centrifugal Pump May Be Your Next Best Pump Selection

End Suction Pumps Intro To Pumps

Which One Is Better Split Case Or End Suction Pump Youtube

Desmi Vertical Nslv And Horizontal Nslh End Suction Centrifugal Pump Youtube

Which Centrifugal Pumps To Choose Horizontal Vs Vertical

Vertical Inline End Suction Water Pumps Delivery Information News Shijiazhuang Depon Pump Limited Company

The Case For Vertical Inline Close Coupled Pumps

In Modern Hvac System Design Pump Style Matters Pumps Systems

End Suction Pumps Intro To Pumps

Lined End Suction Pump Intro To Pumps

Vertical Inline Pumps Intro To Pumps

Choosing The Right Fire Pump Steven Brown Associates

Types Of Pumps Used In Process Industry Centrifugal Pumps The Piping Talk

End Suction Pump Centrifugal Durco Flowserve Chemical Process Ireland

Fire Fighting End Suction Pump China Pump Manufacturers Industrial Pumps System Solution